UK REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is a regulatory framework that governs chemical substances manufactured or imported into Great Britain, which includes England, Scotland, and Wales. Established in 2021 following Brexit, this regulation was modelled after the European Union (EU) REACH regulation. It is important to note that while Northern Ireland is part of the UK, it continues to adhere to EU REACH regulations. The primary goal of UK REACH is to ensure the safe use of chemicals to protect human health and the environment. To achieve this, businesses must register the substances they intend to manufacture or import with the Health and Safety Executive (HSE). The registration process includes evaluating the safety of these substances, obtaining authorization for high-risk chemicals, and complying with restrictions on certain hazardous materials. In summary, UK REACH aims to promote innovation within the chemical industry while maintaining rigorous safety standards.

UK REACH explained

UK REACH is a regulation that applies to the majority of chemical substances that are manufactured in or imported into Great Britain (GB) (England, Scotland, Wales). This can be:

SA Compliance offers customized services to assess chemicals, ensuring their safety for both humans and the environment throughout their entire life cycle. We utilize the extensive expertise of skilled toxicologists, ecotoxicologists, environmental chemists, and health, safety, and environmental (HSE) experts to meet the requirements of chemical regulations, including the UK-REACH legislation. For further clarification please contract us on email: info@sacompliance.co.uk.

Importers bringing chemical substances into Great Britain from the EU, EEA, Northern Ireland, or other regions must register any substance they import in quantities of one ton or more per year with the Health and Safety Executive (HSE) under UK REACH regulations. This registration requirement applies unless the suppliers have designated an Only Representative (OR) to manage these responsibilities. Importers classified as downstream users under EU REACH are also subject to this requirement. Specifically, UK companies that imported chemicals from the EU/EEA before the end of the transition period and relied on EU REACH registrations earlier in the supply chain are now recognized as importers under UK REACH. They must ensure they have valid registrations for the substances they import.

Additionally, substances found in articles must be registered if they are intended to be released during use. For example, scented children’s toys may contain fragrance substances that are released to enhance the product’s appeal by providing a pleasant smell. Compliance obligations under UK REACH vary based on each company’s role in the supply chain. Manufacturers producing or extracting a substance through chemical synthesis, smelting, or extraction must also obtain valid registrations for those substances under UK REACH. Failure to comply with UK REACH regulations can result in serious consequences, including loss of market access, strain on internal resources, and damage to reputation. To help manufacturers navigate these challenges, SA Compliance offers a comprehensive UK REACH solution. This solution provides valuable insights to help avoid penalties for non-compliance and costly enforcement actions, thus facilitating manufacturers’ expansion into the UK market.

For further clarification, please contact us via email at info@sacompliance.co.uk.

Importers of chemical substances entering Great Britain from outside the country must register these substances with the Health and Safety Executive (HSE) under UK REACH regulations if the import quantity is one ton or more per year. This requirement is waived if the supplier has appointed an Only Representative (OR) to handle these obligations. Companies classified as importers under UK REACH must ensure that they have a valid registration for the substances they import. Non-GB manufacturers wishing to import their substances into Great Britain can appoint an Only Representative to manage their UK REACH responsibilities. The OR helps maintain access to the GB market by alleviating some of the importer’s obligations.

Failure to comply with UK REACH regulations can lead to severe consequences, such as losing market access, putting a strain on internal resources, and damaging reputation. To assist manufacturers in navigating these challenges, SA Compliance offers a comprehensive UK REACH solution. This solution provides valuable insights to avoid penalties for non-compliance and costly enforcement actions, thereby facilitating manufacturers’ expansion into the UK market.

For further clarification, please contact us via email at info@sacompliance.co.uk.

Substances of Very High Concern (SVHCs) are chemicals that pose significant hazards, including the potential to cause cancer and other dangerous effects. These substances can remain in the environment for extended periods and accumulate in the bodies of animals over time. According to Article 57 of UK REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), certain hazardous substances can be classified as SVHCs. The aim of UK REACH is to ensure the safe use of chemicals while protecting human health and the environment.

This is accomplished by collecting data on chemical properties and uses, assessing the associated risks, and implementing restrictions or authorizations for SVHCs. Producers of items containing an SVHC at a concentration greater than 0.1% by weight (w/w) at the component level must disclose its presence. For example, in an electronic device, the component level refers to any item listed in the bill of materials (BOM). A key principle of this regulation is “once an article, always an article.” This means that if an SVHC is present in a small resistor at a concentration above 0.1%, the manufacturer of the final assembly must declare it, regardless of the final product. This requirement is consistent across both the EU and the UK. A significant challenge for suppliers is determining whether their final products contain substances from the Candidate List of SVHCs. SVHCs can be found in various consumer products, but manufacturers and retailers may not always be aware of their presence.

SA Compliance takes on the responsibility of assisting customers and manufacturers who are concerned about how current or proposed SVHCs might impact their products. SA Compliance assesses all chemicals and can provide statements confirming SVHC-free compliance to ensure clear communication throughout the supply chain.

For further clarification, please contact us via email at info@sacompliance.co.uk.

Substances of Very High Concern (SVHCs) are chemicals that pose significant hazards, including the potential to cause cancer and other dangerous effects. These substances can remain in the environment for extended periods and accumulate in the bodies of animals over time. According to Article 57 of UK REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), certain hazardous substances can be classified as SVHCs. The aim of UK REACH is to ensure the safe use of chemicals while protecting human health and the environment.

This is accomplished by collecting data on chemical properties and uses, assessing the associated risks, and implementing restrictions or authorizations for SVHCs. Producers of items containing an SVHC at a concentration greater than 0.1% by weight (w/w) at the component level must disclose its presence. For example, in an electronic device, the component level refers to any item listed in the bill of materials (BOM). A key principle of this regulation is “once an article, always an article.” This means that if an SVHC is present in a small resistor at a concentration above 0.1%, the manufacturer of the final assembly must declare it, regardless of the final product. This requirement is consistent across both the EU and the UK. A significant challenge for suppliers is determining whether their final products contain substances from the Candidate List of SVHCs. SVHCs can be found in various consumer products, but manufacturers and retailers may not always be aware of their presence.

SA Compliance takes on the responsibility of assisting customers and manufacturers who are concerned about how current or proposed SVHCs might impact their products. SA Compliance assesses all chemicals and can provide statements confirming SVHC-free compliance to ensure clear communication throughout the supply chain.

For further clarification, please contact us via email at info@sacompliance.co.uk.

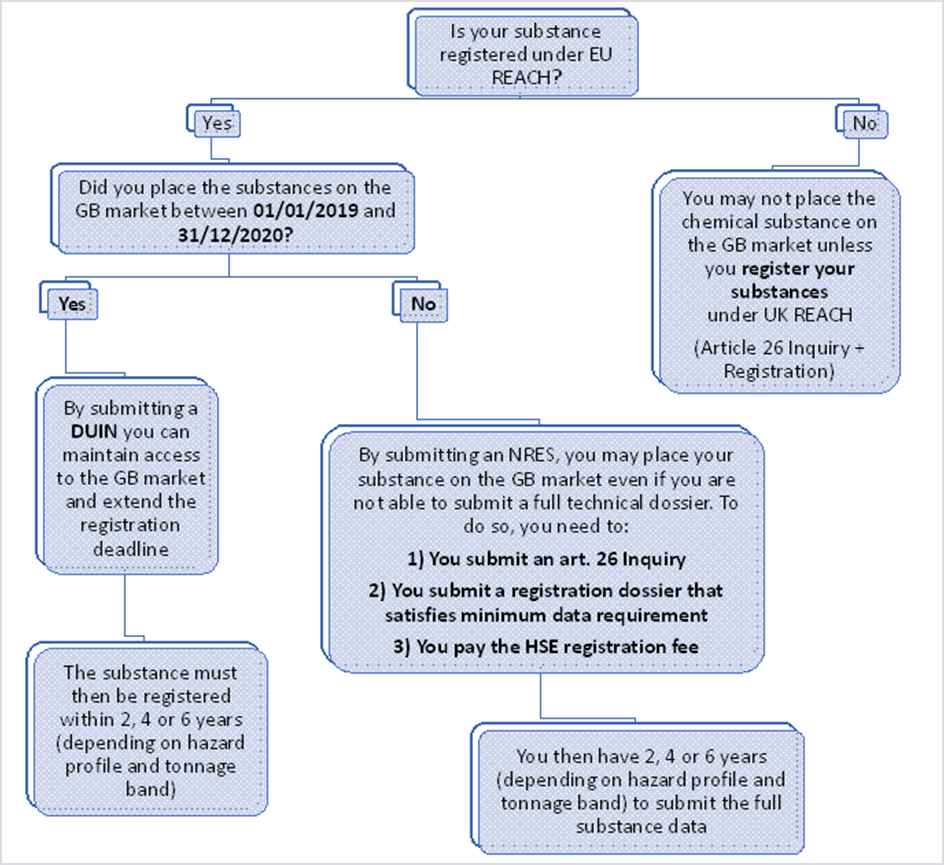

Companies that manufacture or import one or more substances must register those substances with the Health and Safety Executive (HSE). Substances contained in articles must also be registered if they are intended to be released during use. The registration process begins with an Article 26 inquiry, followed by the registration. The inquiry dossier must include detailed information about the company and the substance manufactured or imported into Great Britain (GB). The requirements for compiling the Inquiry Dossier align with those established under EU REACH. Under UK REACH, registrations must be submitted jointly, adhering to EU REACH’s “one substance, one registration” principle. However, each legal entity must submit its registration dossier and pay the associated fee. As a registrant under UK REACH, manufacturers must gather information about the properties and uses of substances they manufacture or import in quantities exceeding one tonne per year. We at SA Compliance also assess the hazards associated with these substances and evaluate any potential risks posed by their use. Registration applies to substances on their own, in mixtures (formulated products), and, in certain limited cases, to substances contained within articles. Chemical substances already regulated under other legislation, such as medicines or radioactive materials, are either wholly or partially exempt from REACH requirements. The “one substance, one registration” principle applies under UK REACH. This means that manufacturers and importers of the same substance should engage in “joint registration” to minimize the use of animal testing and share the costs associated with generating registration data. A fee is typically charged for the registration of new substances. If there are multiple registrants for a substance, the co-registrants need to agree on who will serve as the ‘lead registrant.’ SA Compliance is here to assist customers and manufacturers concerned about how current or proposed Substances of Very High Concern (SVHCs) might affect the registration process. We assess all chemicals and can provide statements confirming compliance issues to ensure clear communication throughout the REACH registration process. For further clarification, please contact us via email at info@sacompliance.co.uk.

In Great Britain and Northern Ireland, various types of electrical and electronic equipment (EEE) are regulated to control the levels of specific hazardous substances and chemicals they may contain. The purpose of this regulation is to protect both human and animal health. Manufacturers, importers, and distributors—including retailers—are collectively known as economic operators. They are responsible for ensuring that the EEE they sell or offer in the GB and NI markets complies with these regulations.

Economic operators must be able to trace their suppliers and maintain sales records for up to 10 years after the EEE is introduced to the market. To demonstrate compliance, they need to keep technical documentation, which includes a Declaration of Conformity, records of conformity assessment procedures, and other production control documents, such as test reports. Failure to comply with UK RoHS regulations can result in serious consequences, including loss of market access, strain on internal resources, and damage to reputation. To help manufacturers navigate these challenges,

SA Compliance offers a RoHS solution developed in collaboration with supply chain and regulatory experts. This solution provides valuable insights to help avoid penalties for non-compliance and costly enforcement actions, thus facilitating manufacturers’ expansion into the UK market.

For further clarification, please contact us via email at info@sacompliance.co.uk.

The RoHS Directive prohibits the use of certain hazardous substances in electrical and electronic equipment (EEE). This directive applies to all appliances sold in the European Union after July 1, 2006.

SA Compliance fully adheres to the requirements of the RoHS Directive, which is essential for any business, product manufacturer, or retailer selling electrical and electronic equipment in the EU, particularly if their products contain any of the ten restricted substances. Non-compliance with the RoHS Directive can lead to serious consequences, including loss of market access, strain on internal resources, and damage to reputation.

To help manufacturers navigate these challenges, SA Compliance offers a RoHS solution developed in collaboration with supply chain and regulatory experts. This solution provides valuable insights to help avoid penalties for non-compliance and costly enforcement actions, facilitating manufacturers’ expansion into both the UK and EU markets. For further clarification, please contact us via email at info@sacompliance.co.uk.

The Safety Data Sheet (SDS) is an essential document that communicates safety information throughout the supply chain. SDSs provide detailed information about hazardous chemicals in a product, including necessary protective measures, health risks, first aid procedures, environmental dangers, physical properties, transport classifications, and disposal instructions, among other important details. Manufacturers and suppliers are required to provide Safety Data Sheets to their customers.

SA Compliance offers SDSs for all its products in various languages and formats that meet country-specific regulations, including those in the UK, EU, USA, and China. These SDSs outline the hazards associated with chemical products and provide guidance on safe handling, storage, and emergency procedures in the event of an accident. Although SDSs are crucial for chemical products, their creation demands technical expertise and can be time-consuming. Moreover, they must be regularly reviewed to ensure compliance with changing regulations. While some finished products may not require SDSs for consumer use, hazards related to manufacturing, storage, transportation, and retail can arise during production, making SDSs necessary to address these risks. Creating an SDS is an effective way to provide essential information for the safe use and disposal of products. We can produce SDSs that comply with global regulations, including CLP (UK), CPL (EU), and OSHA (USA).

The Great Britain Classification, Labelling, and Packaging (GB CLP) Regulation came into effect on January 1, 2021. This regulation requires manufacturers, importers, and downstream users of substances and mixtures to properly classify, label, and package chemicals before they are placed on the market in Great Britain. This requirement ensures that information regarding hazards is effectively communicated throughout the supply chain. To make the GB CLP fully operational in Great Britain, the EU CLP Regulation has been amended, leading to some changes in the requirements. For example, under the new arrangements, EU harmonised classifications are now legally binding as mandatory classifications in Great Britain. This allows Great Britain to make its own decisions regarding mandatory hazard classification and labelling, including whether to align with the decisions made by the EU.

Various laws worldwide aim to identify the hazardous properties of chemicals through a process known as classification. This classification results in labels and safety data sheets communicating these hazards to users. However, differences in hazard descriptions from one country to another can create confusion. For instance, a chemical labelled “toxic” in one country might not carry the same designation elsewhere, posing barriers to international trade. Recognizing the need to address this critical global issue, the Earth Summit in Rio de Janeiro in 1992 and the World Summit in Johannesburg in 2002 emphasized the importance of harmonizing chemical regulations. The United Nations (UN) developed the Globally Harmonized System (GHS) to classify and label chemicals to support the growing international market for chemical substances and mixtures while protecting people and the environment and facilitating trade. The GHS is a standardized system used globally to convey the hazardous properties of industrial and consumer chemicals, complementing the UN’s “Transport of Dangerous Goods” system. To create the GHS, the UN convened experts from various countries to establish consistent criteria for classifying chemicals based on their health, environmental, and physical hazards.

Additionally, the GHS standardizes communication requirements for labelling and safety data sheets. It is important to note that the GHS is not a formal treaty but a non-legally binding international agreement. Consequently, countries or trading blocs must develop local or national legislation to implement the GHS. The European Union’s CLP Regulation (Classification, Labelling and Packaging) incorporates the GHS across its member states. Following the UK’s exit from the EU, the CLP Regulation has been retained in Great Britain’s law with minor adjustments and is now referred to as the GB CLP Regulation. These arrangements ensure that Great Britain continues to align with the GHS.

At SA Compliance Service, we strive to ensure that information regarding the hazardous properties of chemicals is accessible worldwide, thereby enhancing the protection of human health and the environment during the handling, transport, and use of chemicals.

Additionally, we assist our customers in understanding that the GHS provides a framework for harmonizing chemical regulations at national, regional, and global levels, which is vital for facilitating trade. SA Compliance Service helps our customers prepare all necessary documentation to suit various modes of transportation, including Rail (RID), Road (ADR), Sea (IMDG), Inland waterways (ADN), and Air (ICAO T.I./IATA) on a global scale.

For further clarification, please email us at info@sacompliance.co.uk.

Companies involved in the manufacturing, importing, using, or distributing hazardous mixtures marketed in the UK or EU are required to complete Poison Centre Notifications (PCN) and submit them to the relevant authorities: the National Poisons Information Service in the UK and the European Chemicals Agency (ECHA) in the EU. These mandatory documents provide crucial information about mixtures classified as having health or physical hazards. They include details on emergency health responses and preventative measures that poison centres use during incidents or exposures.

SA Compliance offers a comprehensive PCN service to assist companies in meeting their poison centre obligations in the UK and EU markets. Our services include generating Unique Formula Identifiers (UFI), preparing dossiers, and handling submissions.

Additionally, SA Compliance supports customers and manufacturers who are concerned about how current or proposed PCN legislation may impact their products. We assess all chemicals and facilitate the generation of Unique Formula Identifiers (UFI), dossier preparation, and submission to ensure clear communication throughout the process.

For further clarification, please email us at info@sacompliance.co.uk.

Our SDS subscription service allows customers to delegate the responsibility of maintaining essential documents to our experienced SDS team, with 26 years of expertise in this area. Customers can select from various packages, including alerts and notifications for upcoming changes, consultancy services, and an annual review to ensure their documents are current. Additionally, a limited number of revisions are available as needed. With year-round support, you will save valuable time and effort, gain assurance that your completed SDS is technically accurate, and maintain compliance with constantly changing regulations. Customers can choose SDS services for the UK, EU, USA, or any country worldwide.

For further clarification, please contact us via email at info@sacompliance.co.uk.

Material characterization has many applications in product development and production. It involves the chemical analysis of materials to create a “fingerprint” that identifies their composition. This information minimizes toxicological testing for new designs and allows for adjustments in production and design. Chemical identification should also be conducted on incoming raw materials and on a lot-to-lot basis during production. While we do not have laboratory facilities, we partner with regulated laboratories to meet our customers’ needs. For further clarification, please contact us via email at info@sacompliance.co.uk.

Various agencies, including those governing UK REACH and UK RoHS, require different levels of biocompatibility testing based on their classifications. We are here to assist in completing all necessary tests through approved laboratories. For further clarification, please contact us via email at info@sacompliance.co.uk.

The Waste Framework Directive (Directive 2008/98/EC) serves as the legal foundation for the SCIP database. This directive supports the European Union’s transition to a circular economy by implementing measures to prevent or reduce the harmful effects of waste generation and management on the environment and human health. The primary goal of the Waste Framework Directive (WFD) is to ensure the harmonized, safe, and secure management of industrial waste materials while promoting the efficient use of resources. In the amended Waste Framework Directive, which came into effect in July 2018, the European Chemicals Agency (ECHA) was tasked with creating a database that contains information on articles that include substances of very high concern (SVHCs) as listed in the REACH Candidate List. This database is known as the SCIP Database (Substances of Concern In Articles As Such or in Complex Objects (Products)). The SCIP database gathers information about products that contain these candidates and aims to enhance transparency regarding hazardous substances for consumers, authorities, and waste operators. SA Compliance facilitates the collection of due diligence data related to SCIP in your supply chain by automating your processes. For further assistance, please contact us via email at info@sacompliance.co.uk.

The Safety Data Sheet (SDS) is an essential document that communicates safety information throughout the supply chain. SDSs provide detailed information about hazardous chemicals in a product, including necessary protective measures, health risks, first aid procedures, environmental dangers, physical properties, transport classifications, and disposal instructions, among other important details. Manufacturers and suppliers are required to provide Safety Data Sheets to their customers.

SA Compliance offers SDSs for all its products in various languages and formats that meet country-specific regulations, including those in the UK, EU, USA, and China. These SDSs outline the hazards associated with chemical products and provide guidance on safe handling, storage, and emergency procedures in the event of an accident. Although SDSs are crucial for chemical products, their creation demands technical expertise and can be time-consuming. Moreover, they must be regularly reviewed to ensure compliance with changing regulations. While some finished products may not require SDSs for consumer use, hazards related to manufacturing, storage, transportation, and retail can arise during production, making SDSs necessary to address these risks. Creating an SDS is an effective way to provide essential information for the safe use and disposal of products. We can produce SDSs that comply with global regulations, including CLP (UK), CPL (EU), and OSHA (USA).